Fairline Targa 50 – Pre Purchase Survey & Warranty Claims (#730/796)January 7, 2016

We undertook a Pre Purchase Survey of a very nice c2011 Fairline Targa 50. As a direct consequence of which several months later we then represented (Expert Witness) the then owner in respect of Dispute / Warranty Claims.

Our attendance / inspection of Warranty-Work in Progress on a month by month basis, being agreed with both Fairline and their Agent

The background to this being that as part of the buyer’s purchase T&Cs, Fairline and their agent / broker agreed to warranties covering ship’s services etc.

Though there were several (42 items) warranty claims, one significant claim was for the ingress of water through the recessed deck hatches located both port and starboard in the teak faced side decks.

These recessed side deck hatches cover the electrical motors operating the main saloon (very large) windows which are designed to lower into the saloon side linings. However it was discovered that debris (ex production) had blocked these locker drains, a consequence of which the lockers over time subsequently filled with sea water – flooding the electric window motors / winding gear and eventually flooding into the guest cabins below via ducting, destroying deck head linings, side linings, carpets & electrical gear etc.

We also understand that this same problem has happened to other Fairline Targa 50s, fitted with the same main saloon electrical window operation – potential buyers beware

In support of the Fairline Agent involved they undertook and eventually rectified all warranty items and carried out work above and beyond the actual claim – to the satisfaction of the owner. However many items claimed were as a direct result of poor quality control in the Fairline building programme.

For more information contact European Marine Services Ltd. Marine Surveyors & Consultants

Tel : 01603 327 123 www.europeanmarinesurveys.com

Ocean 30 – An unexpected recent build (#988)December 2, 2015

The Ocean 30 also built as the Moonraker 30, were built mainly between 1968 – c 1980 and therefore to conduct a pre-purchase survey on a boat reportedly built early 1991 is unexpected – However the date appears to check out as the engine number is c 1990

The moulding was by AquaFibre of Rackheath, the semi-displacement round bilge with a long central box keel design by John Bennett – the vessel being rated as an extremely good sea boat.

Herbert Woods of Potter Heigham were the predominant fitters-out until 1975, plus Broom Boats of Brundall and RA Nunn after that. Between 1968 – 1970 Bell Buxton produced the Moonraker 30 based on the Ocean hull. Over 1,000 Ocean 30’s were built. Most can be found on inland waterways but these boats are quite capable of going to sea.

The boat we inspected was an aft cockpit version with a bathing platform, davits, single diesel engine with twin bilge keels – again unusual. An aft cabin version was also produced mainly as a hire boat but the usable deck space (and aft cabin space) in this version is somewhat limited

On our Ocean 30 the following items required attention:

Fuel tank access / piping conformity Auto bilge pump operation

Recommend the LPG water heater installation is checked by a qualified engineer

For more information contact European Marine Services Ltd – Marine Surveyors & Consultants Tel : 01603 327 123 www.europeanmarinesurveys.com

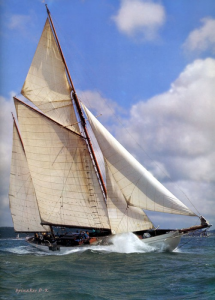

Gaff Rigged Wood Ketch ‘Cynara’ – Marine Survey in Japan (# 00159-07)December 1, 2015

Japan – A long way to go for a Marine (Insurance) Survey, but a great adventure & experience

Several years ago back in 2007 we had the pleasure and honour to be instructed by a large Japanese Corporation to undertake a Condition Survey / Valuation of this most famous 110′ gaff rigged ketch built in 1927 by Camper & Nicholsons UK. (Launched as ‘Gwendolen’) We therefore thought that this condition / valuation survey would make an interesting blog

Dimensions: Auxilliary Gaff Rigged Ketch ‘Cynara’ LOA 109′ 8″ x Beam 18′ 7″ x Draft 11′ 3″

Rumour is that ‘Cynara’ belonged at one time to Winston Churchill. The Cynara itself doesn’t have a log. It also doesn’t have a certificate to prove Churchill’s ownership. However the Japanese owner’s believe this to be true

During her early years she was owned by Lord Northampton, her longest owner to date, and was later used for charter in the Mediterranean where she entertained the likes of Prince William of Gloucester. Another of her accolades involves the film industry where Cynara starred in the film, Arriverderci Baby ! with Tony Curtis and Zsa Zsa Gabor.

Cynara (73.4 tons) was sailed to Japan in 1973 to become a promotional tool for ‘Seibu’, a Japanese department store. Cooking classes were held on ‘Seibu’s luxury yacht’ as part of the companies’ ‘edutainment concept’ and she regularly went out on sunset cruises. During this time her devoted skipper took serious pride over the maintenance of the vessel, especially when it came to his varnish!

View aft standing on bow sprit Deck view View from beneath with a 11′ 3″ draft

Japan (Tokyo) is a long way to go to undertake a condition survey & market valuation, plus travelling south to Kanagawa (marina) which took a day by car, but had the pleasure of the bullet train ride back to Tokyo – a very rewarding experience

If anyone wants to know what it is like staying in a local Japanese hotel with communal bathing and sleeping on a mat on the floor plus eating ‘real’ Japanese food, don’t ask.

Plan of Cynara

For more information contact European Marine Services Ltd – Marine Surveyors & Consultants Tel : 01603 327 123 www.europeanmarinesurveys.com

Princess 35 – A lot of boat for the price (#969)November 22, 2015

A recent pre purchase survey on a 1985 Princess 35 powered by twin Volvo Penta 165hp diesel engines, showed us that you can buy a ‘lot of boat’ for a budget price

This Princess 35 is an estuary / coastal GRP motor cruiser with twin inboard diesel engines and standard shaft propulsion. The hull design is medium V with chines

This marine survey was carried out at St Olaves Marina. Where earlier this year they upgraded their lifting capability with the addition of a 50 tonne travel lift. Being only 1/2 hour from Breydon Water / Gt Yarmouth, St Olaves Marina now offers a readily accessible lifting service to boat owners and passing yachtsmen

As is usual most boats of this vintage that moor on the Norfolk Broads / inland waterways this Princess being no exception, the underwater surfaces will tend to have osmosis. Interestingly boats moored in salt water will (to a much greater extent) tend to not have osmosis.

All GRP structures immersed in water will absorb water through the gel coat, to what extent this happens is dictated by numerous factors. Water temperature, thickness of gel coat, quality of construction, quality of materials, temperature during build, and salinity of the water all have some bearing on the absorbency of your hull.

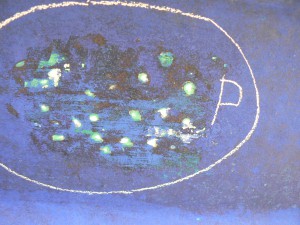

Visual evidence of osmotic blistering Associated moisture meter readings

Very simply, the problem is caused by water penetrating the gelcoat and entering the laminated structure. This water takes in solution free chemicals salts and becomes denser than salt water on the outside of the hull. This creates a differential pressure and since water will not compress blisters form on the outer side of the gelcoat

Today the presence of osmosis does not cause great concern. If there are blisters but they are small and not too many they are not likely to have any significant effect on the structural strength.

Other than the above osmosis which is considered relatively minor there were not too many negative factors, and at the price paid the new owner is able to bring this Princess 35 up to top specification and enjoy many more years of top quality cruising

In summary the following items required attention:

Raw water seacock valve security Fuel tank piping conformity

Battery storage Auto bilge pump satisfactory operation

For more information contact European Marine Services Ltd – Marine Surveyors & Consultants Tel : 01603 327 123 www.europeanmarinesurveys.com

Moore’s 1950s Wood Classic Cruiser – Still Going Strong (# 00973)

We undertook a pre purchase survey on this ex hire boat ‘classic’ being in private hands for some time and were pleasantly surprised at the results

This 26′ carvel constructed mahogany on oak (ex hire R Moore & Sons (Wroxham) Ltd) built in 1950 and therefore now some 65 years plus of age, is still going strong and in remarkable good structural condition – being an OAP and of ‘retirement’ age

The bottom is heavily tarred which has gone along way to protect the structure and the presentation topsides / superstructure is beautifully varnished giving an overall classic appearance – per original build

The above photos being typical of the build and current condition

To be expected – not everything was in perfect structural condition however, there being some wet rot in bottom planking (not extensive) with wet rot in a bulkhead beneath the side decks. The BMC 1.5L diesel engine and exhaust manifold was heavily corroded -but overall nothing too much and all recoverable

Examples of engine / manifold corrosion present

The interior is typical of this era with (by today’s standards) a very basic rear saloon / cabin / galley area with a settee / double bed and not much else – but this is all part of its charm. A great escape from television and the world of the internet

For more information contact European Marine Services Ltd – Marine Surveyors & Consultants Tel : 01603 327 123 www.europeanmarinesurveys.com

Beneteau Oceanis 323 – A great yacht at a bargain price (#965)October 30, 2015

Boat of the Year – Oslo 2004 ” A Great Charter Yacht “

We recently conducted a pre purchase survey on a Beneteau 323 which was stored ashore at the Titchmarsh Marina, Walton on the Naze, Essex – A beautiful location with stunning views across to Harwich. The sun was also shining making this inspection more pleasurable

The first thing to be said about this Beneteau was the price, being sold at an agreed bargain price of around £15 – £20k less than the selling price she would command on the South Coast.

The Beneteau Oceanis 323 inspected had a fixed fin ballast keel and single rudder as apposed to a lifting keel and twin rudders

The stainless standing rigging was all in good shape although the running rigging could do with being ‘washed’ (in a net bag in the washing machine) as it has been exposed to all weathers.

An excellent view of the fin ballast keel and rudder

An excellent view of the fin ballast keel and rudder

As the alloy mast was in position we could only report on the ‘rigging’ etc as seen at deck level. Not being sail makers we do not comment on the sails – and its just not practical to open up large mainsails / foresails for examination other than in a sail loft.

One novel feature that we did not appreciate at the time was that the wheel / helm console in the spacious aft cockpit can be rotated 90 deg fore-aft to allow for easy side passage.

This yacht passed survey with flying colours but one comment is why do manufacturers / boat builders mix mild steel washers with stainless bolts as is the case with the keel bolts !

For more information contact European Marine Services Ltd – Marine Surveyors & Consultants Tel : 01603 327 123 www.europeanmarinesurveys.com

Delta RIB 5.5m – High Speed Accident Damage at Sea (#00950)October 8, 2015

Delta RIB 5.5m

Acting as Marine Insurance Loss Adjusters, European Marine Services was recently instructed to inspect and report as follows:

- Casualty details including views on what caused the damage.

- Review the estimates for repairs to the third party vessel and advise whether you consider the work fair, reasonable and casualty related.

- Provide us with your reserve estimate.

- Witness details, where applicable.

- Subrogation* details, where applicable ( * Insurer’s right to pursue a third party)

- Photographs of the damage.

The accident happened at speed and resulted in extensive damage to the GRP hull plus rupturing the inflatable tube (sponson) with the RIB being close to sinking. Fortunately no one was hurt

View of extensive damage to GRP hull

What is important is not the results of our investigation / inspection or how the accident happened which remains confidential, but that the insurance company required the following documentation as part of its claim consideration from the insured parties

- Warranted all vessels classed and certified

- Warranted all vessels are fit to encounter the ordinary peril of seas, rivers, lakes or navigable waters, properly crewed, equipped, fuelled, provisioned and with all equipment in proper working order. Seaworthiness applies not only to the physical conditions of the hull but to all its parts, equipment and gear.

- Were the crew fully qualified up to RYA Level 2 power boating, VHF AND Sea Survival courses.

The above clauses (extracts) being part of the Insured Marine Policy Terms & Conditions ie. the small print

This being important to boat owners whom have the misfortunate to make a claim in the event of an accident

Therefore make sure that as an owner / operator / user of small high speed craft that you are fully aware of the Insurance T&Cs,

If not you may possibly find that you have no cover

Sealine S38 – Structural Hull Defects (# 920)September 27, 2015

Acting in the capacity of an Expert Witness (CPR 35 compliant) we recently inspected a Sealine S38 for inherent structural hull defects

The background to this being as follows:

Sealine’s are generally considered to be lightly built and several models suffer from stress cracking / flexing of the hull.

The Sealine S38 suffered from an exceptionally weak hull GRP layup making it prone to vertical and longitudinal stress cracking – this being due to a miscalculation of the original layup specification by their design department *

The principal area of fault lying between the bow thruster tube and the forward engine bulkhead

Back in 2005 / 2006 Sealine agreed that additional strengthening work was required on the hull of the Sealine S38. This however was carried out on a boat-by-boat basis, and as we understand it no general recall notice was issued and Sealine only took action when customers complained.

Consequently there are many Sealine S38’s still in the market place which have not been strengthened

As Sealine are no longer in business in their original form – warranty / claims are no longer valid.

An estimate as to the cost of rectification can be anything between £15,000 – £25,000 depending upon who carries out the work

* Acknowledgement: Paul Homer, Homer Marine Ltd

For more information contact European Marine Services Ltd – Marine Surveyors & Consultants Tel : 01603 327 123 www.europeanmarinesurveys.com

Freeman 22 | Freeman 23 | Freeman 27 | A month of ‘classic’ boat surveysSeptember 9, 2015

This is a month of carrying out Pre Purchase Surveys on the ‘classic’ Freeman Range of inland waterway craft that were built between the 1960s and 1970s and still going well after 50 years

As they say when waiting for bus along come three ……….

” History ” Acknowledgement to the official Freeman Cruisers website

The first 22ft Freeman Cruiser emerged in 1957. By the 1970’s the factory was employing 125 people, building three 23ft and one 26ft cruiser each week and one Freeman 30 every 2/3 weeks. There were 4 or 5 factory lines at a time: It took 25 men to build a single boat. Some 6,000 boats were produced by the time John decided finally to retire, he now lives in France. Incidentally, the last boat to be built was a Freeman 27 in October 1983.

In 1964 the model was changed bringing in the new 22 which is now known as the Mk 2 (hence the previous boat is referred to as the Mk 1). The cabin was raised so that you could walk right through,- the well renowned “step in the deck” was established. As with the 22 Mk 1 there is a narrow beam version of the 22 Mk 2 at 6ft 10″ wide which can also be used on the canals.

Traditional Freemen 22 with a ‘stepped’ deck

Traditional Freemen 22 with a ‘stepped’ deck

Traditional Freeman 23 with level decks

Traditional Freeman 23 with level decks

Freeman 27 a radical design change

Freeman 27 a radical design change

A common feature of the earlier Freeman’s design was the flexing of the forward decks due to lack of reinforcement within the GRP such as a balsa core. In both the 22 and 23 this was the reality.

In some earlier models a bolt-on encapsulated wood keel is added for improved steerage so attention must be made to the keel bolt fastenings

Both the smaller models had the historic Ford Watermota inboard four cylinder petrol engine, which were still performing well. However when undergoing a survey particular attention must be made to the petrol system installations to include earth bonding.

For more information contact European Marine Services Ltd. Marine Surveyors & Consultants

EMS also undertake Boat Safety Inspections & Engine Inspections

www.europeanmarinesurveys.com

Tel: 01603 327 123

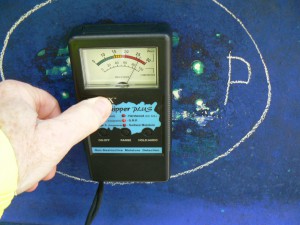

Aquafibre 28 – The benefits of copper coating (#937)August 30, 2015

European Marine Services recently carried out a pre purchase survey of a very nice and well maintained Aquafibre 28

The significant difference about this boat is that despite being some 25+ years old and permanently moored on inland waterways there was no evidence of any hull deterioration or osmosis.

The lack of osmosis being primarily due to the early application of a professionally applied copper coating – no antifouling applied over.

View of Aquafibre 28 Copper coating

Most of the well known range of Aquafibre GRP hull & superstructure mouldings (25′ – 55′) were built / fitted out by other boatyards around the UK, as Aquafibre were primarily a GRP boat moulding company based at Rackheath nr Norwich Norfolk and not boatbuilders. Broom Boats being a major builder of boats moulded by Aquafibre. Aquafibre ceased manufacturing in 2009

Back to this Aquafibre 28 …..

This design has the individual twin sliding large sunroofs over the forward driving position and saloon, making for a very nice relaxation area for socialising and watching the world pass by.

Decent sliding sunroof Corroded extended skeg assembly / rudder

The significant problem was that there was no access in this particular boat to the bilge spaces and hull sides for internal examination, being due to screwed floors, furniture / panelling / soft side linings etc and the distinct absence (again) of access hatches and removable panels.

Relatively minor problems included the non operation of the auto bilge pump float switch and a corroded mild steel extended skeg assembly and rudder blade – no zinc anodes being fitted

For more information contact European Marine Services Ltd – Marine Surveyors & Consultants Tel : 01603 327 123 www.europeanmarinesurveys.com